🔧RTO Working Priciple

Regenerative Thermal Oxidizer (referred to as three-chamber RTO)

Three-chamber RTO is one of the core devices for treating VOCs in the current coating and environmental protection fields. Its core working principle is to achieve high-temperature incineration of exhaust gas and efficient recovery of heat through the alternating processes of heat storage, heat release, and purging in three regenerators, ultimately decomposing organic compounds (VOCs) in the exhaust gas into harmless CO₂ and H₂O.

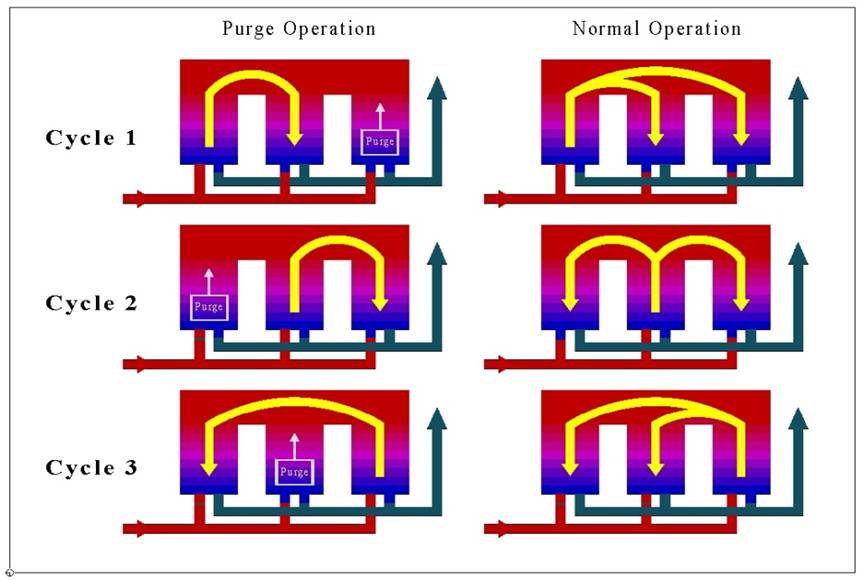

A. Core Working Principle (Four-Step Cycle)The operation of the three-chamber RTO relies on the precise switching of valves, enabling the three regenerators (usually referred to as Chambers A, B, and C) to take turns performing three tasks: "intake heating", "purified exhaust", and "purging regeneration", forming a continuous treatment cycle. Each cycle is roughly divided into the following four steps;

- Exhaust Gas Preheating (Heat Storage Stage)The VOCs-containing exhaust gas to be treated enters one of the regenerators (e.g., Chamber A) through a valve. The exhaust gas is heated by the heat storage medium (mostly ceramic fillers) filled in the regenerator, and its temperature rapidly rises from room temperature to near the incineration temperature (approximately 750-850℃).

- High-Temperature Incineration (Oxidation Stage)The preheated exhaust gas enters the combustion chamber and is heated to 800-950℃ with the help of auxiliary fuel (such as natural gas). At this temperature, the VOCs in the exhaust gas undergo oxidation reactions, decomposing into CO₂ and H₂O, with a purification rate of over 99%.

- Heat Recovery (Heat Release Stage)The purified high-temperature gas (approximately 800-950℃) enters the second regenerator (e.g., Chamber B), transferring heat to the heat storage medium. Its own temperature rapidly drops to 100-150℃ before being discharged through the chimney. At this point, the heat storage medium in Chamber B completes "heat storage", preparing for the next round of preheating.

- Switching and Purging (Regeneration Stage)When the heat in the heat storage medium of Chamber A is completely released and Chamber B has finished heat storage, the valves switch. The exhaust gas then enters Chamber B for preheating, the purified gas enters Chamber C for heat release, and at the same time, a small amount of clean air is introduced to purge Chamber A. The purpose of purging is to remove residual untreated exhaust gas in Chamber A, preventing direct emission of exhaust gas during switching and ensuring treatment efficiency.

B. Core Advantages of Three-Chamber DesignCompared with two-chamber RTO, the three-chamber structure solves the problem of exhaust gas leakage during switching by adding a "purging chamber", with the main advantages as follows:

- Continuous and Stable Operation: The three regenerators work alternately without interrupting the input of exhaust gas, enabling 24-hour continuous treatment.

- Extremely high thermal efficiency: The heat recovery rate of the regenerator can reach over 95%, which significantly reduces the consumption of auxiliary fuel and results in low operating costs.

- Thorough treatment: The purging process avoids the problem of "direct emission of untreated waste gas", ensuring that the VOCs removal efficiency remains stable at over 99%.

The RTO system features extremely low energy consumption, using ceramics as the heat transfer and storage medium. When the VOCs concentration reaches 2-3 g/Nm³ or higher, the RTO can achieve zero energy consumption in waste gas treatment by incinerating the VOCs gas at 800℃.

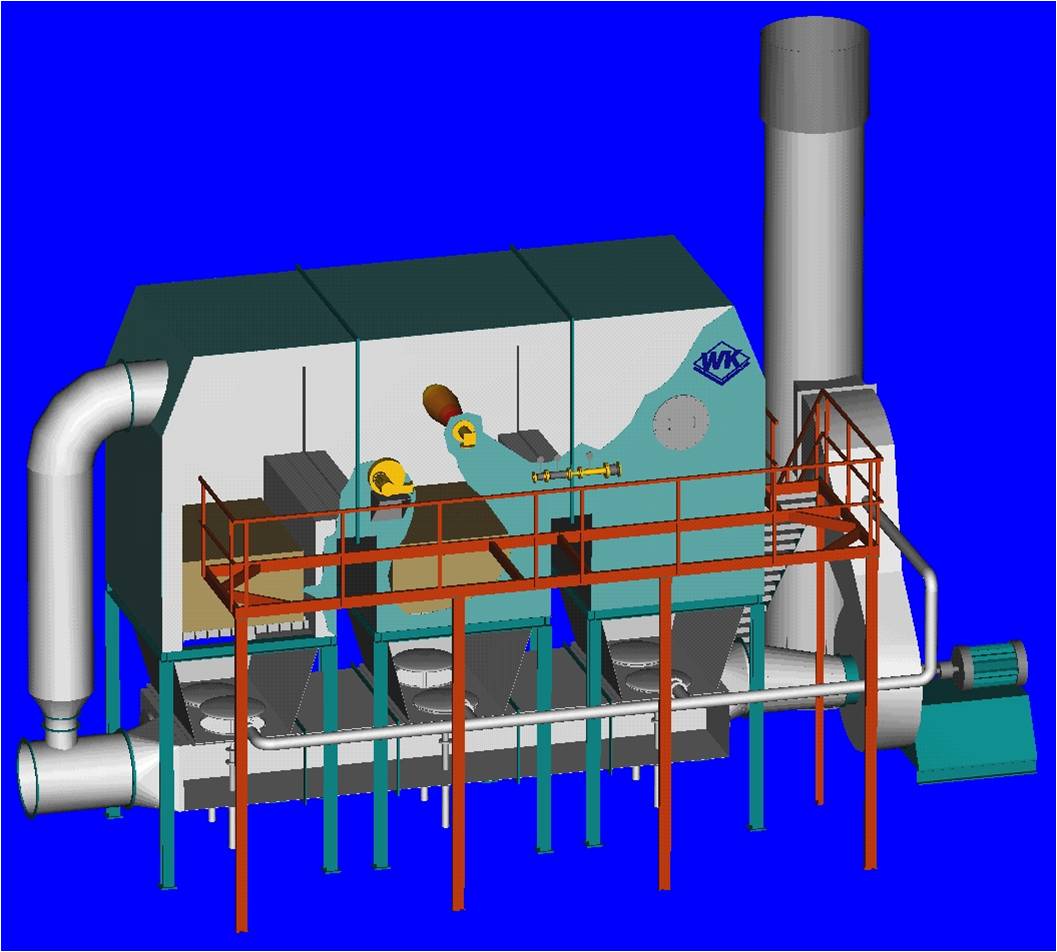

Regenerative Thermal Oxidizer (RTO) 3D Schematic Diagram

RTO - Regenerative Thermal Oxidizer Working Proces

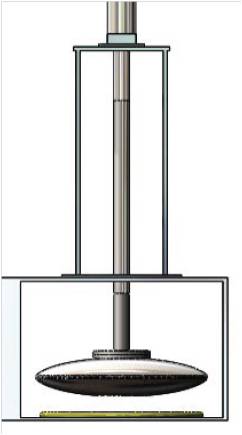

The special mushroom-type design of the lift valve ensures no deformation or damage during long-term continuous operation at high temperatures, with a service life of over 20 years.

The special arc-shaped design guarantees the uniformity of exhaust gas entering the heat storage ceramic body, ensuring a heat exchange efficiency of up to 96% or higher.

The elastic ceramic sealing structure prevents direct contact between metal and metal seals, thus achieving 100% damper tightness. Leakage-free operation is the guarantee for the high-efficiency operation of the RTO system, ensuring a maximum treatment efficiency of up to 99.95% or higher.

During production shutdown, the valve is 100% sealed with excellent thermal insulation performance. When restarting production after 12 hours, it only takes 15 minutes to reach the operating temperature, realizing high efficiency and energy saving. Additionally, no condensates will form in the ceramic body, thus avoiding carbon deposition and blockage of the ceramic body.

The excellent sealing performance ensures no risk of high-temperature hot gas returning to the inlet when the RTO is shut down, making it safe and reliable.

The ceramic sealing rings are high-temperature resistant, durable, and low-cost, and can be easily replaced in the maintenance channel.

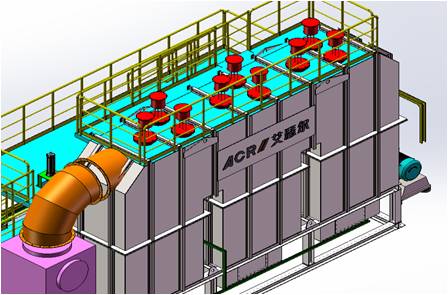

Regenerative Thermal Oxidizer (RTO)

| Item | Details |

|---|---|

| Processing Objects | Malodorous waste gas, organic waste gas (such as coating spraying waste gas, coating waste gas, etc.) |

| Processing Capacity | 5,000~100,000 Nm³/h |

| Removal Efficiency | The removal efficiency of three-chamber and multi-chamber RTO can reach more than 99.97% |

| Application Industries | Automobile industry (VOCs concentration + incineration or circulating air + incineration in production line spraying workshop), printing/color steel plate coating industry, aluminum product factories, electronics factories, chemical plants, pharmaceutical factories, etc. |

| Working Principle | The Regenerative Thermal Oxidizer (RTO) utilizes the excellent thermal insulation and heat conduction properties of ceramics to preheat the waste gas directly in the ceramics, which greatly reduces the temperature difference during combustion and lowers energy consumption. It mainly has the following characteristics: |

| Core Features | 1. The temperature in the oxidation combustion chamber is constant at 800℃, ensuring the oxidation temperature of the waste gas . 2. Ceramic heat storage material is adopted, with a heat transfer efficiency of ≥96%. The temperature difference between the inlet and outlet of the waste gas is ≤40℃, allowing direct emission . 3. Lifting-type mushroom-shaped valves (with zero leakage) are used to ensure the treatment efficiency . 4. The residence time of the waste gas is more than 1 second, enabling sufficient oxidative cracking . 5. Heat self-sustainment can be achieved when the waste gas concentration is 2-3g/m³ . |

🔧Application Cases of RTO

Three-Chamber RTO Equipment in FAW-Volkswagen Automobile Factory

Electrically Heated Three-Chamber RTO Equipment for Carbon-Neutral Technology in Changan Automobile Factory

Electrically Heated Three-Chamber RTO Equipment for Carbon-Neutral Technology in Changan Automobile Factory

Three-Chamber RTO (Coating) of Trelleborg Engineered Fabrics

Three-Chamber RTO of SAIC-GM-Wuling Baojun Automobile Factory

Three-Chamber RTO Equipment of Great Wall Motor