🔧Product Introduction

The dual-component automatic mixing machine replaces manual mixing, with its core advantage addressing the inherent drawbacks of manual operation:Manual mixing is prone to ratio imbalance due to weighing errors (often exceeding ±5%), leading to poor coating curing (e.g., softening, embrittlement); uneven stirring can cause defects such as shrinkage cavities and gloss inconsistencies. Additionally, manual mixing is inefficient, difficult to adapt to mass production, and entails material waste (due to pot life out-of-control) and safety risks (direct contact with coatings).

The expected benefits are significant:

- Enhanced quality stability: Mixing ratio error ≤±1%, uniform mixing, and reduced rework;

- Improved efficiency: Realizes continuous feeding to match production line rhythms;

- Cost reduction: Minimizes material waste and labor input;

- Improved operational safety: Lowers health risks, making it better suited for large-scale, high-quality production requirements.

🔧Working Priciple

The ALT-Mix enables ratio control of Component A : Component B within a preset range (e.g., 0.1:1 to 50:1).Its workflow can be summarized as follows:

When the operator sets the required formulation (including ratio, dosage size, flow rate, etc.) on the control panel and the system is activated in "Mix Mode", the controller first opens Dose Valve A for Component A, allowing it to flow into the mixing module. Flow Meter A monitors the flow rate/volume, and the controller tracks the data based on the preset K-factor (cc/pulse). Once Component A reaches the preset volume, Dose Valve A closes; then Dose Valve B for Component B opens, enabling Component B to flow into the mixing module (monitored by Flow Meter B). After both components enter the mixing module, they are uniformly mixed via a static mixer before being delivered to the spray gun/process end.

During spraying/discharging, if a Gun Trigger signal is detected, the system will continuously repeat the above dosing process in an "alternating dosing" manner: A → B → A → B… until stopped.

Note: The term "alternating" here refers to the alternating opening of the dose valves for Component A and Component B. It does not mean alternating changes in the flow rates of the two components, but rather sequential feeding to ensure precise ratio control.

🔧Application Scenarios

- Electronics industry and IT industry requiring precision metering

- Spray coating and adhesive dispensing for automotive interior and exterior parts requiring precision metering

- Use of special coatings

- Leather coating for automotive airbags

- Heat-resistant coating for exhaust pipes

- Manual spray gun for single-color and multi-color applications

- Fixed automatic gun or automatic spray gun with reciprocator for single-color and multi-color applications

- Multi-gun, multi-color, and multi-component automatic metering and mixing applications

- Air spray gun, air-assisted spray gun, electrostatic spray gun, and bell cup gun for robotic applications

- For water-based electrostatic coating: Fiber optic sensors are required for the dual-component system; please inquire separately.

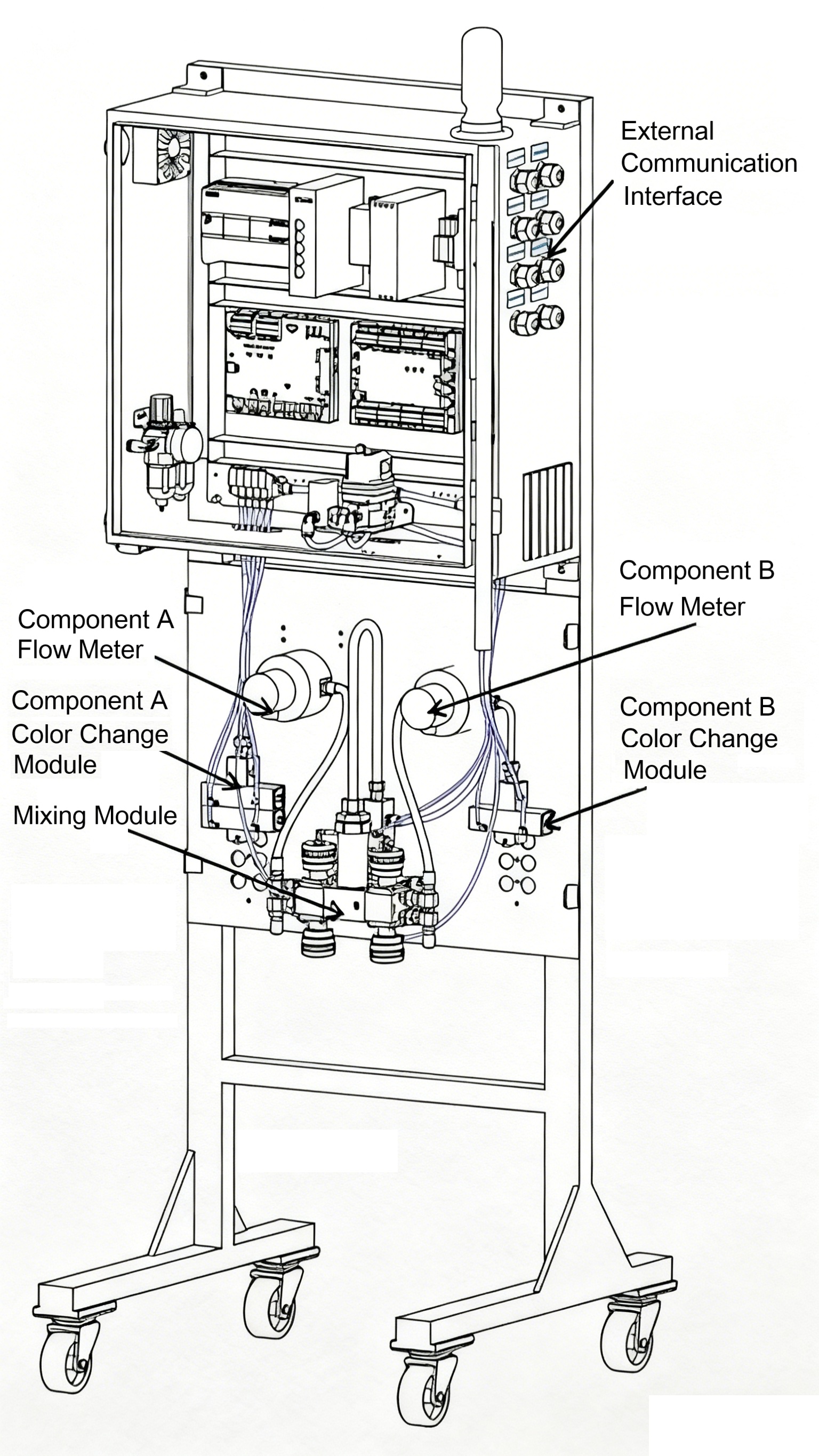

🔧2K auto dosing & mixing machine with paint flow meter

| Specification Item | ALT-Mix-CC Model | ALT-Mix-KK Model |

|---|---|---|

| Dual-Component Mixing & Metering Model | ALT-Mix-CC | ALT-Mix-KK |

| Mixing & Metering Method | Flow Meter Measurement | Flow Meter Measurement |

| Maximum Mixing Flow Rate | 3L/min (Decreases with increasing viscosity) | 3L/min (Decreases with increasing viscosity) |

| Paint Output Stability | ±1% | ±1% |

| Maximum Paint Working Pressure | 1MPa (Low-Pressure Spraying) | 1MPa (Low-Pressure Spraying) |

| Maximum Air Working Pressure | 0.7MPa | 0.7MPa |

| Operating Air Pressure Range | 0.45 to 0.7MPa | 0.45 to 0.7MPa |

| Air Supply Requirement | 0.6 to 0.7MPa | 0.6 to 0.7MPa |

| Air Filter Inlet Size | 3/8 NPT(F) | 3/8 NPT(F) |

| Built-in Air Filter (Machine-Integrated) | Minimum 5μm, Clean/Dry | Minimum 5μm, Clean/Dry |

| Spraying Atomization Air Filter (Integrator-Supplied) | Minimum 30μm, Clean/Dry | Minimum 30μm, Clean/Dry |

| Compatible Paints | 1K/2K paints; Solvent-based & water-based paints; Polyurethane; Epoxy resin; Acid-cured varnish; Moisture-sensitive isocyanate | 1K/2K paints; Solvent-based & water-based paints; Polyurethane; Epoxy resin; Acid-cured varnish; Moisture-sensitive isocyanate |

| Adaptable Paint Viscosity | 20~3,000 cps | 20~3,000 cps |

| Paint Filtration Device (User-Supplied) | 60, 80, or 100 mesh | 60, 80, or 100 mesh |

| Paint Outlet Connection | 1/4 NPT(M) | 1/4 NPT(M) |

| Maximum Mixing Ratio Range (Accuracy varies slightly with viscosity and ratio) | Continuous Mixing: 0.1:1 ~ 50:1Alternating Mixing: 0.1:1 ~ 30:1 | Continuous Mixing: 0.1:1 ~ 50:1Alternating Mixing: 0.1:1 ~ 30:1 |

| Operating Temperature Range | 10 to 50°C (Heating function optional) | 10 to 50°C (Heating function optional) |

| Paint-Contact Materials | SUS316, SUS304, Tungsten Steel, PTFE, Perfluoroelastomer, UPE, Ceramic | SUS316, SUS304, Tungsten Steel, PTFE, Perfluoroelastomer, UPE, Ceramic |

| Optional Flow Meter Type | Gear Flow Meter | Mass Flow Meter |

| Suitable Fluids | Most solvent-based/water-based coatings, resins, etc. | Excellent performance for high-precision, fast-response, low-viscosity, and easy-clogging fluids |

| Equipment Dimensions (L×W×H) | 600×600×1750 mm | 600×600×1750 mm |

| Standalone Weight | Approximately 80 kg | Approximately 80 kg |

| Power Supply | 200/240VAC, 50/60Hz | 200/240VAC, 50/60Hz |

| Installed Power | 0.2kW | 0.2kW |

*This information is for reference only. Actual equipment specifications and performance shall be subject to the quotation and contract.

🔧 Flow meter selection of 2K auto dosing & mixing machine

*Either flow meter for the base component or the hardener may be selected at will.

| Comparison Scope | Gear Flow Meter C | Coriolis Mass Flow Meter K |

|---|---|---|

| Fluid Viscosity Adaptability | Suitable for medium-high viscosity, stable viscosity fluids (e.g., resins, curing agents) | Unaffected by viscosity and density, suitable for low viscosity or fluids with large viscosity fluctuations |

| Range of Accuracy | ±0.5%~±1%, meeting general industrial requirements | ±0.1%~±0.5%, suitable for high proportion precision scenarios (e.g., high-end coatings) |

| Requirements for Fluid Cleanliness | Sensitive, strict filtration required (impurities easily wear gears) | Better tolerance to small amounts of impurities |

| Investment cost | Lower | Higher |

| Maintenance Difficulty | Simple (mainly replace easily worn parts like gears) | Complex (requires regular sensor calibration, with precise structure) |

| Operating Condition | Greatly affected by temperature and pressure fluctuations (viscosity changes will reduce accuracy) | Unaffected by temperature and pressure fluctuations, with strong stabilit |