This is a very precise question. It not only focuses on the core function of environmental protection equipment but also takes energy efficiency into account, which is one of the key directions for industrial energy conservation.

餘熱及能源再利用

熱油熱交換器

熱油熱交換器

熱水交換器

熱水交換器

氣熱交換器

氣熱交換器

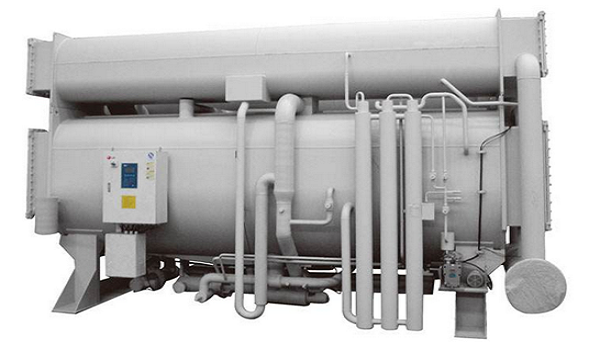

溴化鋰製冷機組

溴化鋰製冷機組

蒸汽鍋爐

蒸汽鍋爐

預熱式陶瓷過濾器

🔧 Waste Heat Utilization Methods: Direct, Indirect, and Power Generation/Work Production

1️⃣ Direct Utilization: Directly Meeting Heat Demand

It directly supplies waste heat as thermal energy for production or daily use without intermediate conversion, resulting in the minimum energy loss.

- Used for production process heating: Such as heating waste gas before VOCs treatment to improve incineration efficiency; or heating raw materials and semi-finished products in the factory to replace traditional boilers.

- Used for on-site daily needs: Providing winter heating for employee dormitories and office buildings, or supplying hot water for production and daily use.

2️⃣ Indirect Heat Exchange: Transferring Heat Through Media

When the temperature and working conditions of waste heat are not suitable for direct utilization, heat is transferred to other media through heat exchange equipment to flexibly meet different needs.

- Generating steam/hot water: Using waste heat boilers to generate low-pressure steam for driving small equipment; or generating high-temperature hot water for production cleaning, heating, etc.

- Preheating combustion-supporting air/fuel: Using waste heat to preheat the combustion-supporting air or fuel of RTO incinerators, reducing fuel consumption and improving the thermal efficiency of incinerators.

3️⃣ Power Generation/Work Production: Converting to High-Grade Energy

When the waste heat temperature is relatively high (usually ≥300℃), thermal energy can be converted into electrical energy or mechanical energy through energy conversion devices to achieve high-value utilization.

- Waste heat power generation: Adopting Organic Rankine Cycle (ORC) technology, which uses waste heat to heat organic working fluids and drive turbines to generate electricity, suitable for medium and high-temperature waste heat.

- Driving auxiliary equipment: Using waste heat to drive absorption chillers to provide cooling for workshops; or driving steam turbines to drive fans, water pumps and other equipment.

🔧 Comparison of Different Reuse Methods

| Reuse Method | Core Equipment | Applicable Waste Heat Temperature | Energy Conversion Rate |

| Direct Utilization | Pipes, Heat Exchangers | Medium-low temperature (≥80℃) | High (≥80%) |

| Indirect Heat Exchange | Waste Heat Boilers, Plate Heat Exchangers | Medium-high temperature (≥150℃) | Medium (50%-80%) |

| Power Generation/Work Production | ORC Units, Steam Turbines | High temp(≥300℃) | LOW(15%-30%) |